|

| Manufacturer of : Jaw Crusher, Primary jaw crusher. Primary jaw crusher Exporters, Primary jaw crusher Suppliers from India |

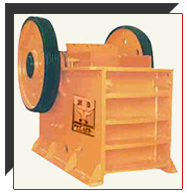

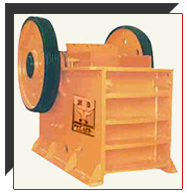

Primary Jaw Crushers are ideally suited for crushing of bigger size hard granite stone, Iron Ore, black trap rock, river gravel, lime stone, Iron ore , coal etc to minimize cost of reducing size of blasted boulders in quarry or Mines.

Jaw Crusher from are used to reduce the blasted stone, large boulders or recycled materials to a suitable size for conveying and further processing. They consist of feeders with hoppers to receive surge loads and give a regulated feed to the jaw crushers. The reduced size material is collected on conveyors and carried to convenient transfer points for further processing. These primary plants are also available on single unit structure of a portable plant with structural supports in place where permanent structures are not desirable. Portable plants are available in conventional or low profile models.

|

Jaw Crusher |

Average Capacity in Tons/hr. with Jaw Setting (Closed settings) |

HP |

RPM |

Approx. weight

of M/c kgs |

Inches |

|

1" |

11/2" |

2" |

21/2" |

3" |

31/2" |

4" |

5" |

6" |

7" |

8" |

| MM |

25 |

38 |

50 |

63 |

75 |

90 |

100 |

125 |

150 |

175 |

200 |

24"x12" |

610x305 |

28 |

33 |

40 |

48 |

55 |

62 |

- |

- |

- |

- |

- |

40 |

280 |

7500 Kgs. |

30"x15" |

762x 381 |

- |

- |

50 |

63 |

70 |

80 |

90 |

- |

- |

- |

- |

60 |

280 |

10000 Kgs. |

36"x24" |

914x610 |

- |

- |

- |

- |

80 |

100 |

125 |

150 |

200 |

250 |

275 |

100 |

280 |

15000 Kgs. |

42"x36" |

1066x914 |

- |

- |

- |

- |

- |

150 |

175 |

200 |

250 |

300 |

350 |

150 |

280 |

24000 Kgs. |

|

Application :

Our jaw crushers are ideal for primary and secondary crushing Features :

|

1) |

|

Reduces operating costs |

2) |

|

Reliabe and flexible |

| 3) |

|

Large feed opening and force-feeding action from the inward and downward eccentric movement of the swing jaw increases capacity |

| 4) |

|

With a smaller discharge setting, allowing a higher degree of flexibility with relative equipment |

5) |

|

Positive setting adjustment is easy |

| 6) |

|

Simple, easy to access and with low maintenance |

|

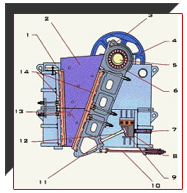

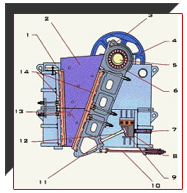

FOR THIS SET UP

|

|

1) |

|

Frame Heavy-duty

design Steel plate welded construction Welded by CO2 shield arc process Stress relieved after fabrication |

2) |

|

Crushing Chamber

Deep crushing chamber Sharp nip angle ensures high crushing |

| 3) |

|

Swing Jaw & Main Bearing Housings

Allows removal from frame as an integral sub assembly Permits onsitesubstitution of a changeover unit in the event of bearing damage Swing Jaw is a robust steel casting |

| 4) |

|

Flywheel

Balances inertia Promotes smooth operation |

5) |

|

Eccentric Shaft

Forged from hardened and tempered chrome molybdenum steel Particularly large diameters to suit heavy -duty application |

| 6) |

|

Bearings

Fag or SKF heavy -duty selfaligning double row bearings on swing jaw and main frame Bath oil lubrication ensures positive lubrication Bearing life in excess of 8 years under typical quarry applications |

| 7) |

|

Hydraulic Cylinder

Allows easy adjustment of discharge setting by moving toggle block to the desired setting |

| 8) |

|

Shim

Allows easy adjustment of closed side setting |

| 9) |

|

Toggle Block |

| 10) |

|

Tension Rod with Spring |

| 11) |

|

Toggle Seat

Allows smooth toggle plate stroke |

| 12) |

|

Toggle Plates

Designed to shear protecting crusher components if noncrushable object is introduced to crusher (i.e. Steel) |

| 13) |

|

Check Plates

Manganese steel castings allow easy replacement 14. Jaw Plates High manganese steel castings can be reversed allowing extended life Wedge \ lug system allows easy replacement |

|

|