|

||

| Home | Company Overview | Product | Inquiry | Contact | ||

Features :-

|

|

vibrating screen is vibrated by the circling motion. The screen line of material is long and the screening specification is various. The screen of very specification is clear. It adopts the tubbish vibrator and eccentric adjustment, with the feature of strong vibration, high screening efficiency and small vibrating noise. This machine is durable, easy to maintain, safe to use. So it is widely used in mining, construction material, transportation, energy and chemical industry for classification. |

Vibrating Screen Features:-1) Simple and dependable Eccentric type system.2) High screening capacity. 3) High durability. 4) No transmission of screen panels. 5) Ready changing of screen plates. 6) Rigid and vibrating resistance screen body. |

Illustration of How our circular vibrating screen operates :

| In screen grading, the material is separated mechanically on screen plates. Rolling bearings in vibrating screens are stressed by high, mostly shock-type loads. Moreover, the bearings, while rotating about their own axis, perform a circular, elliptical or linear vibrating motion. This results in high radial accelerations which additionally stress the bearings, and especially the cages, considerably. The operating speeds are usually very high. As a result, the bearing temperatures are up to 20 to 30 degrees Kelvin higher than in normal applications. In addition, considerable misalignments between the bearing locations and considerable shaft deflections have to be accommodated. |

The Vibrating Screen Technical Data:-

Type |

ScreenSpec (mm) |

Screen Deck |

Screen Mesh (mm) |

Feeder Opening (mm) |

Capacity (t/h) |

Power (kw) |

Vibrating Frquency (r/min) |

Double Amplitude (mm) |

YK1237 |

1200x3700 |

1 |

4~50 |

≤200 |

10~80 |

5.5x2 |

960 |

4~8 |

2YK1237 |

1200x3700 |

2 |

4~50 |

≤200 |

10~80 |

5.5x2 |

960 |

4~8 |

2YK1548 |

4800x1500 |

2 |

3~100 |

≤400 |

30~275 |

15 |

870 |

5~9 |

3YK1548 |

4800x1500 |

3 |

3~100 |

≤400 |

47~275 |

15 |

870 |

5~9 |

2YK1848 |

4800x1800 |

2 |

3~100 |

≤400 |

56~330 |

18.5 |

870 |

5~9 |

3YK1848 |

4800x1800 |

3 |

3~100 |

≤400 |

56~330 |

18.5 |

870 |

5~9 |

2YK1860 |

6000x1800 |

2 |

3~100 |

≤400 |

65~586 |

22 |

870 |

5~9 |

3YK1860 |

6000x1800 |

3 |

3~100 |

≤400 |

65~586 |

22-30 |

870 |

5~9 |

2YK2160 |

6000x2100 |

2 |

3~100 |

≤400 |

81~720 |

30 |

730 |

5~9 |

3YK2160 |

6000x2100 |

3 |

5~100 |

≤400 |

81~720 |

30~37 |

930 |

7~9 |

4YK2160 |

6000x2100 |

4 |

5~100 |

≤450 |

66~720 |

45 |

740 |

8 |

2YK2460 |

6000x2400 |

2 |

3~150 |

≤400 |

150~810 |

30 |

730 |

8 |

3YK2460 |

6000x2400 |

3 |

5~150 |

≤200 |

450~650 |

37 |

740 |

8 |

4YK2460 |

6000x2400 |

4 |

5~150 |

≤200 |

450~650 |

45 |

740 |

8 |

Industrial vibrating screens are used as standard practice where large capacity and high efficiency of screening are desired.

|

|

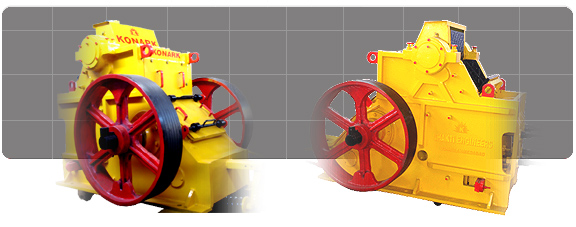

| Vibrating Screen | Vibrating Screen(16 FT. X 05 FT. 4.5 DECK) |

| Vibrating screen for stand alone or multiple installations are manufactured in a wide range of sizes for varying application and production demands. Each unit is compatible with all screening systems and can be integrated into existing and current processing plants. |

|

|

|||||

Crushing Equipments | Grinding Equipments | Screening Equipments | Conveying Equipments | Pelletizing Equipments | Storage Equipments | Feeding Equipments | Mixing Equipments | Separating Equipments | Crushing Plant | Impex Crusher | Jaw Crusher | Lubricated Jaw Crusher | Primary Jaw Crusher | Secondary Jaw Crusher | Cone Crusher | Hammer Crusher | Oil Type double toggle jaw crusher | Stone Crusher Machinery | Stone Crusher Demostration | Roll crusher | Flaker | Circular Vibrating Screen | Vibrating Screen | Vibrating Feeder |

|||||

|